Kansanshi Copper Mine

Stabilisation of open pit wall movements detected by InSAR using horizontal drains.

Abstract

The M15 west slope of the Main Pit at First Quantum Minerals’ Kansanshi copper mine at Zambia is an actively mined eastward facing wall. This study highlights the early warning provided by an InSAR based monitoring service. Displacements were detected along the slope face prompting an intervention using horizontal drains.

To monitor the west slope of the pit, visual inspections, Ground Based Radars (GBR), Robotic Total Stations (RTS) as well as imagery from the radar satellite constellation TerraSAR-X was used. The early warning alert was issued in July 2022 on InSAR displacements estimated using 3 months of imagery acquired at 11 day intervals. Surface movement was detected on several benches with the displacement beginning at the base of the wall and spreading radially and laterally resulting in a circular subsidence pattern. This was suspected to be a precursor to a failure along the slope face. There was no alert of anomalous displacements from the GBR and RTS.

In response to the observed displacements, a mitigation plan was drawn up on site. It was hypothesised that the movements were due to increased pore water pressure. Using horizontal drains and boreholes, the area was to be dewatered. The depressurisation drilling began in November 2022 and continued until December 2022 when it was observed that the rate of movement slowed from 15.1 mm/year to 5.9 mm/year before the onset of the wet season.

Controlling the risk and prevention of the failure allowed for the smooth and continued operation of the trolley lines that were installed to reduce diesel usage. Furthermore, other costs associated with the failure - an increase in the tramming distance, for example - were successfully avoided. Using InSAR as a monitoring tool, timely intervention was possible saving time, operational efficiency as well as quantifiable monetary resources.

1. Introduction

Managing the risks associated with slope instability is critical in the safe and economic operation of open pit mines. Failure of slope walls can result in a pause or closure in mining operations, loss of equipment and loss of life.

The Kansanshi copper-gold mine, located in the North Western Province of Zambia, stands as Africa's largest open pit copper mine, with continuous production since 2005. Mining activities are conducted in two open pits: the Main Pit and North West Pit (see Figure 1). These pits utilize conventional open pit methods, employing electric and hydraulic excavators along with a mixed fleet of haul trucks (Gray, D et al. 2020). The Main Pit, which is the larger pit, spans approximately 3.2 km in length, 1.4 km in width, and reaches a depth of 220 m (O’Ferrall and Simbile, 2020).

The Kansanshi deposit is hosted within the Katanga Supergroup of the Zambian Central African Copperbelt, specifically in deformed metasediments belonging to the Lower Kundulungu Group. Various rock units, including dolomites, dolomitic marbles, schists, and phyllites, constitute the deposit. Copper mineralization is found in two domal structures along the crest of a regional antiform (Gray, D et al. 2020). The dolomitic sequence is responsible for sinkholes that have formed on the edge of the pits where the waste dumps are situated.

Legacy issues are evident in the region surrounding the pit, particularly concerning the northeastern benches that have previously experienced weathering due to exposure to surface water runoff and groundwater, leading to steady creep (O’Ferrall and Simbile, 2020). A similar situation is present at Main 15 upper slope which is adjacent to actively mined areas. It also has an active ramp as part of its structure. The Main 15 upper slope has a fault running through it and has been reported to have elevated pore water pressure.

The depth of weathering around the mine site is down to 50 m below surface, but it extends deeper than 250m in fault zones. Previous failures in the pit have been a result of erosion channels caused by surface water runoff and wedge failures associated with geological structures and pit wall orientation.

Figure 1 a) Location of Kansanshi mine in Northwest Zambia. b) Kansanshi site with the NW Pit and Main Pit Labelled

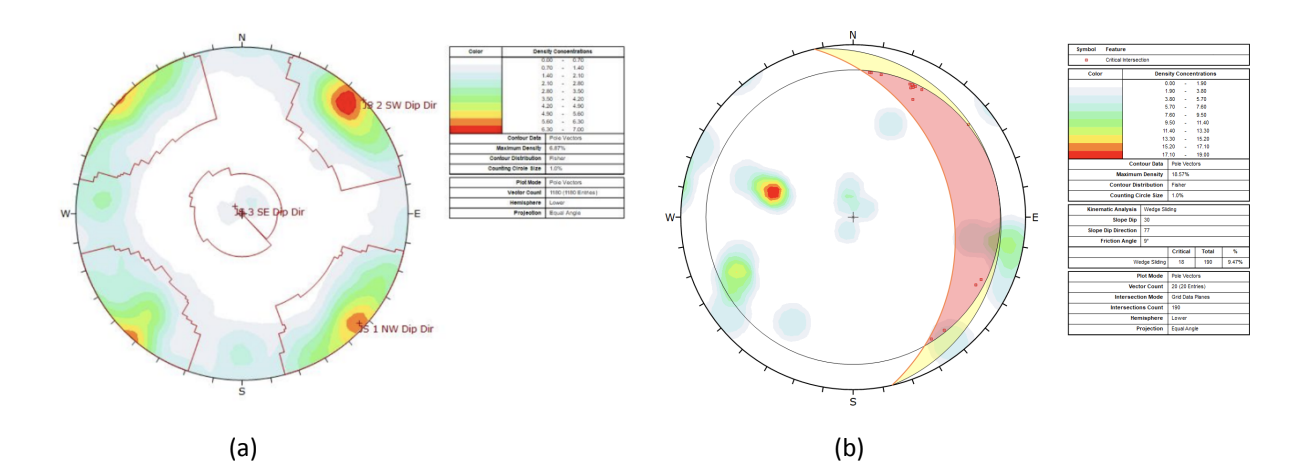

1. Rock Mass

The joint sets at Kansanshi Mine are in general three orthogonal sets with local variation. Two steeply dipping North West – South East and North East – South West striking joint sets and one shallowly dipping, North – South striking joint set (bedding). In Figure 2 the typical joint set poles are represented.

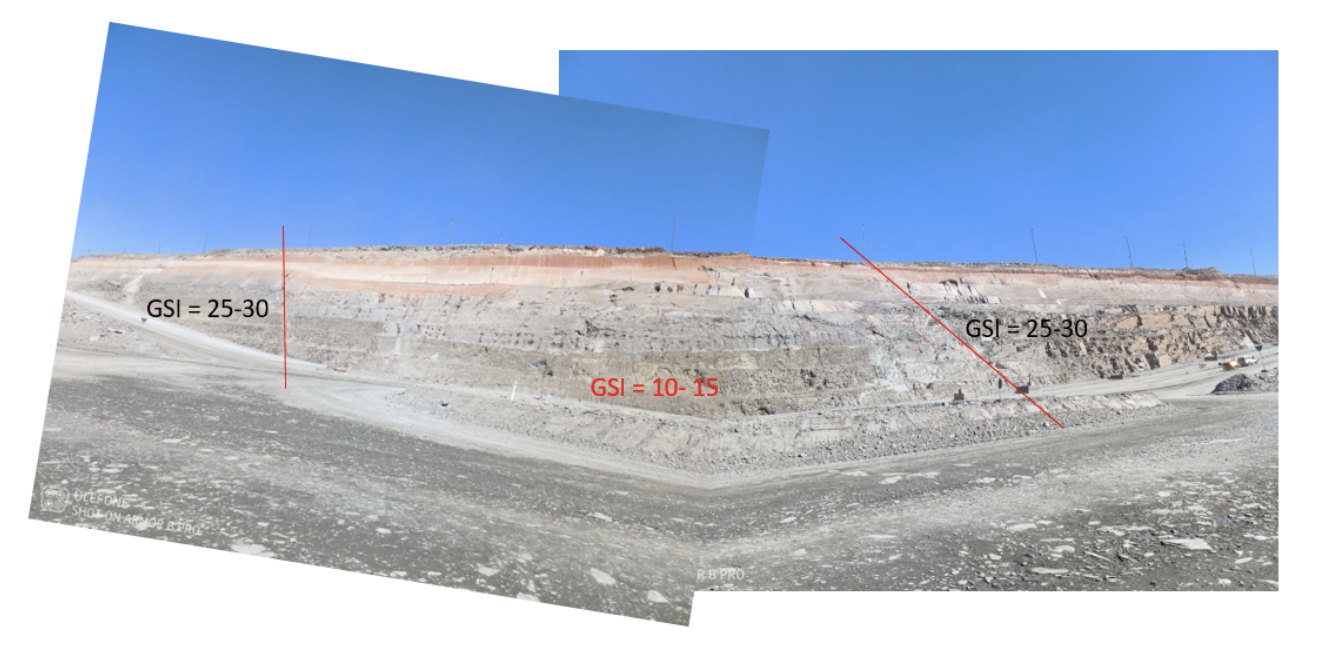

Window mapping was conducted on the Main 15 upper wall. Field observations indicate that the area of movement is confined by two fault planes to the North and South. In Figure 3, the slope and the materials on either side of the fault planes exhibit weathering (GSI = 25 to 30), while the material within the fault zone is highly weathered (GSI = 10 to 15). The Rock Mass Rating (Bieniawski, 1989) for the materials was determined to be 32 (weathered rock) and 14 (fault zone). The underlying mode of failure was identified as wedge failure; however, due to the high degree of weathering, it is believed that the failure mechanism may exhibit more complex behaviour, resembling a circular failure. The susceptibility of slopes to failure is influenced by a combination of internal and external factors, including slope geometry, rock type, geological discontinuities, groundwater conditions, surface drainage, rainfall, seismicity, and human activities (First Quantum Minerals, 2022).

As a result of known legacy issues, heavy seasonal rainfall as well as mining related seismicity, a comprehensive monitoring plan was drawn up to mitigate potential hazards.

Figure 2 (a) Typical joint set orientations for Kansanshi mine, (b) M15 window mapping results (First Quantum Minerals, 2022)

Figure 3 Main 15 ramp intersection showing the difference in material quality

2. Method

2.1 Monitioring Overview

Several methods are used to monitor slope stability at Kansanshi including: Ground Based Radars (GBR’s, one ArcSARand one IBIS FM monitoring Main Pit and one MSR monitoring North West Pit), Robotic Total Stations (RTS), visual inspections and satellite-based optical and Interferometric Synthetic Aperture Radar (InSAR). InSAR is a remote sensing technique that can estimate millimetre-scale displacements on the earth’s surface. InSAR has been used as part of the monitoring strategy at the Kansanshi mine since 2021.

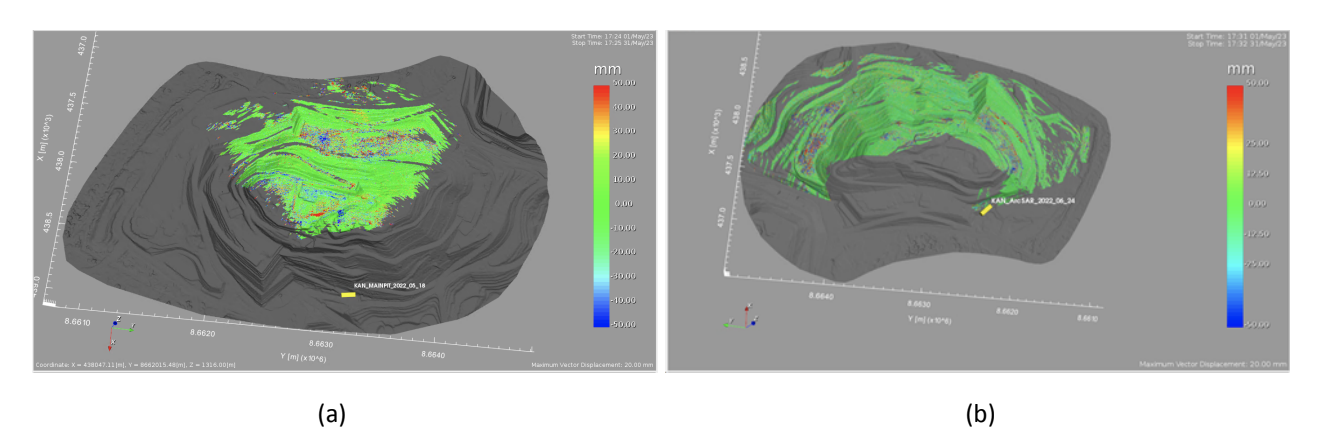

An example of GBR monitoring outputs is shown in Figure 4.

2.2 Satellite Monitoring (InSAR)

InSAR monitoring has been implemented at Kansanshi since 2021. SkyGeo is the current technology partner since 2022. The SAR imagery used is acquired by the TerraSAR-X satellite in StripMap mode every 11 days.

Imagery from both the ascending and descending orbits are utilized. The descending orbit has a steep satellite angle of 27.8 degrees and the ascending orbit has a shallower satellite angle of 54.4 degrees.

SkyGeo performs the InSAR processing using proprietary small baseline subset (SBAS) algorithms. The monitoring service commenced in April 2022 with quarterly updates and a report issued at the end of each quarter. The frequency of reporting was increased to monthly when an alert was issued for the M15 wall. By April 2023, the monitoring frequency for the pits had increased to every 11 days (every time an image is acquired).

A historical baseline analysis was conducted on the site using SAR imagery acquired by the Sentinel-1 satellite from both ascending and descending orbits. The analysis covered the time period from January 2019 to November 2021 for the ascending data set and until March 2022 for the descending data set. The discrepancy in time coverage is due to the disruption of the Sentinel-1B satellite service (Sentinel-1B in-flight anomaly summary report, n.d.). Both orbits have relatively shallow incidence angles around 41 - 42 degrees. The historical baselines were used to assess displacements along the major fault zone, GbRadar blind spots, as well as pre-existing displacement rates on the western slope face. Sentinel-1 was used for the baseline due to retroactive image availability over the area.

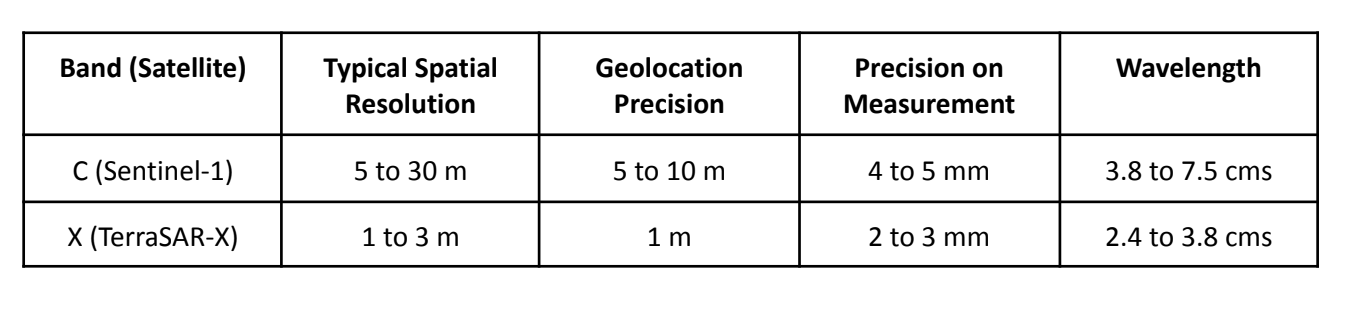

For monitoring the M15 west pit, the TerraSAR-X satellite was used. As an X band satellite, its characteristics include higher geolocation precision, measurement precision, and spatial resolution with respect to C band satellites such as Sentinel-1. This, among other factors, dictated the choice of satellite for monitoring the pits. General characteristics of the two SAR bands are provided in Table 1.

In addition to InSAR, optical satellite imagery from Sentinel-2 was also used to track the changes on site as well as obtain qualitative surface moisture readings of the pit.

The data from historic baselines were used to define thresholds for alerts for the InSAR monitoring service. Five trigger levels were established: Low Risk, Caution, Alert, Critical, and Status Unclear. The “Status Unclear” flag was used to indicate significant loss in data quality where no on-site activities were reported. The minor alert levels such as “Low Risk” and “Caution” were applied to areas that showed displacements but were not anomalous with respect to baseline estimations. “Alert” and “Critical” were applied to displacements that show acceleration with visual signs of large displacement such as tension cracks, sinkholes etc.

2.3 In-situ Monitoring

In-situ monitoring consists of regular visual inspections, Ground Based Radars (GBR), Robotic Total Stations, prisms and VWPs as depicted in Figure 5. A Trigger Action Response Plan (TARP) was developed specifically for the slope monitoring radar systems. It outlined five alert levels (L0 to L4) based on GbRadar velocity thresholds, which were time-bound and varied depending on the type of rock present, such as saprolite, sap rock, fresh material, and loose material (First Quantum Minerals, 2022).

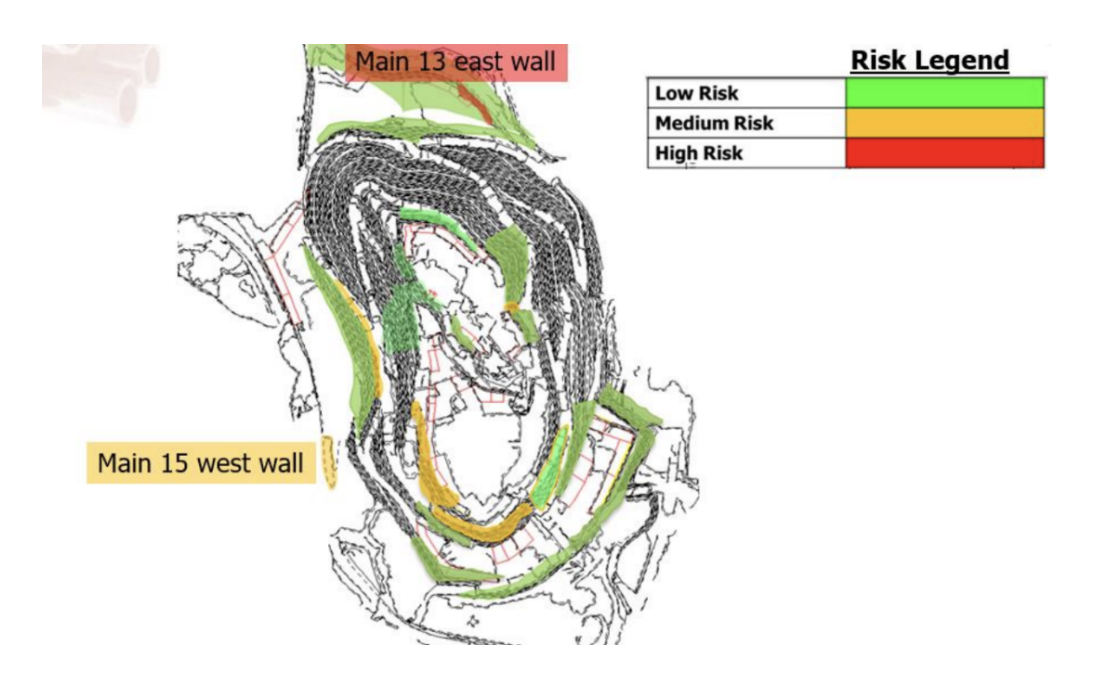

The visual inspections, combined with data from instrumentation and SkyGeo's Early Warning reports, enabled the rock engineering team to create a monthly hazard plan for the pit. The hazard plan categorized different sections of the pit into low, medium, and high-risk zones.

At the onset of the EWS monitoring in June 2022, the hazard levels of the Main pit were classified as per Figure 6. The M15 west wall was denoted to be a medium risk zone due to observed daylighting structures.

Figure 3 Main 15 ramp intersection showing the difference in material quality

Table 1 C and X satellite bands and the general characteristics of their associated datasets

Figure 5 The location and distribution of Robotic total station (large red diamonds), Prisms (black diamonds), Inactive prisms (small red diamonds) and VWP’s (inverted blue triangles)

Figure 6 Example of a hazard map for the Kansanshi Main Pit (First Quantum Minerals, 2022)

3. Observations

3.1 Historic Baseline Observations

The analysis of the historical InSAR baseline report focused on displacements along fault zones, near the cutback region, and blind spots relative to the GbRadar systems. Stable conditions with minimal displacement magnitudes were observed in most non-mined areas.

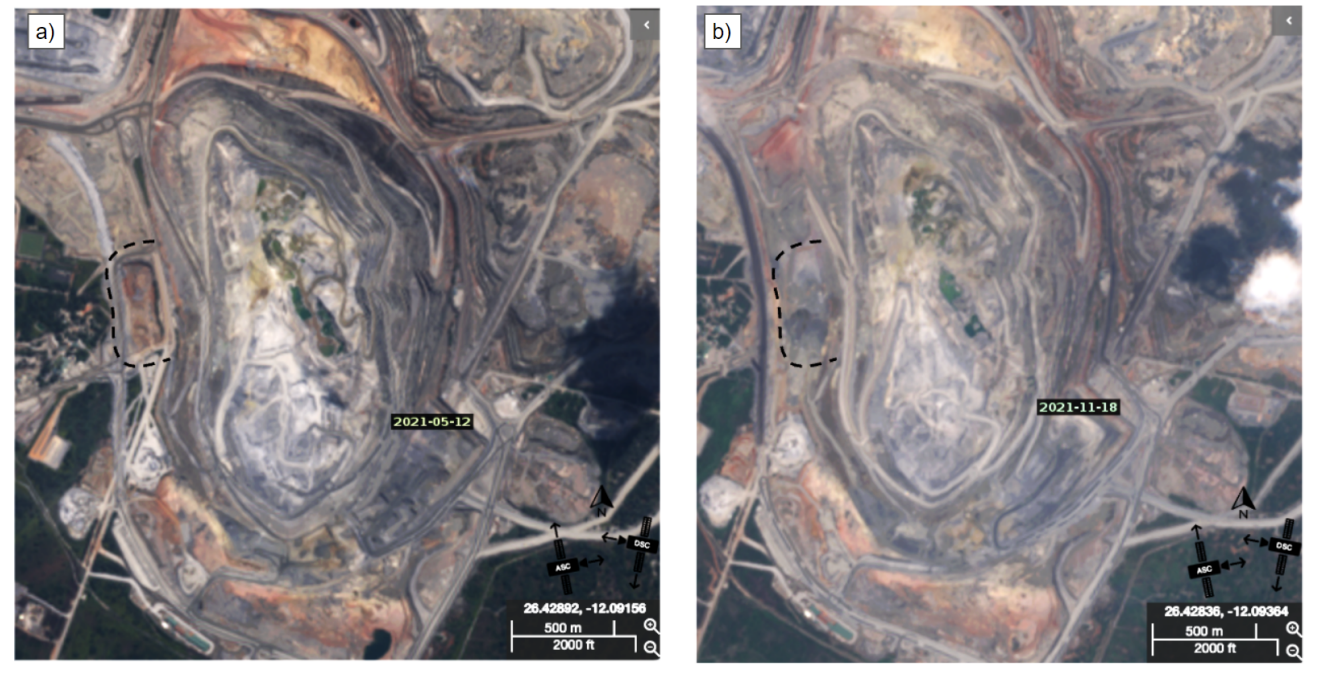

However, the current area known as M15 west wall of the Main pit exhibited consistent displacement over the two-year period. This was of interest because the underlying area was originally a region just beyond the pit crest that housed a waste rock dump as illustrated by optical satellite imagery from Sentinel-2 in Figure 7.

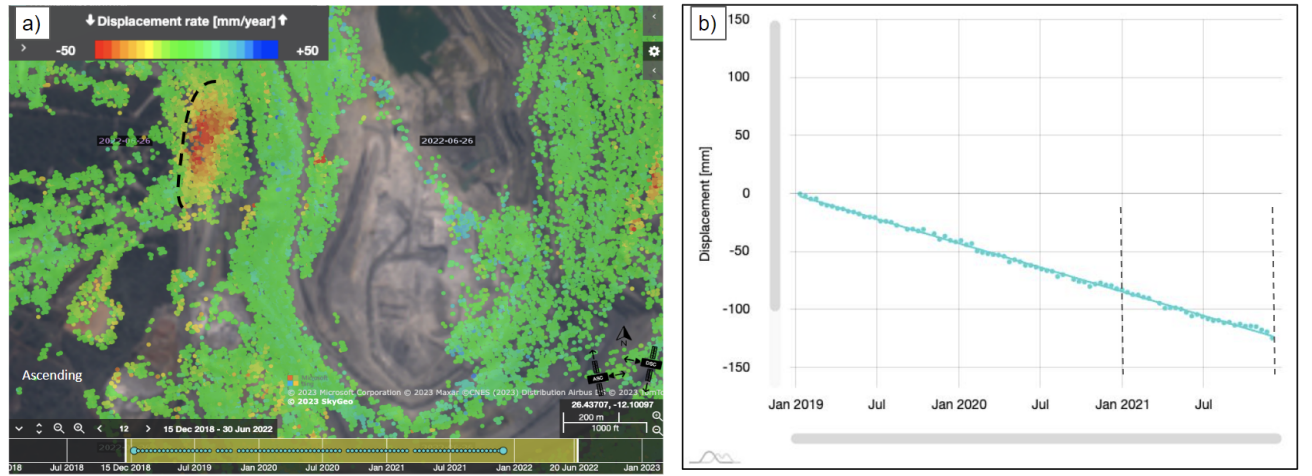

The Sentinel-1 data over the area of interest shows steady subsidence over time with no significant changes to the spatial extent of displacements (Figure 8). During the active mining of the waste rock dump from May to August 2021, a slight reduction in the displacement rate was observed (from -41mm/year to -39mm/year).

3.2 High resolution TerraSAR-X monitoring observations

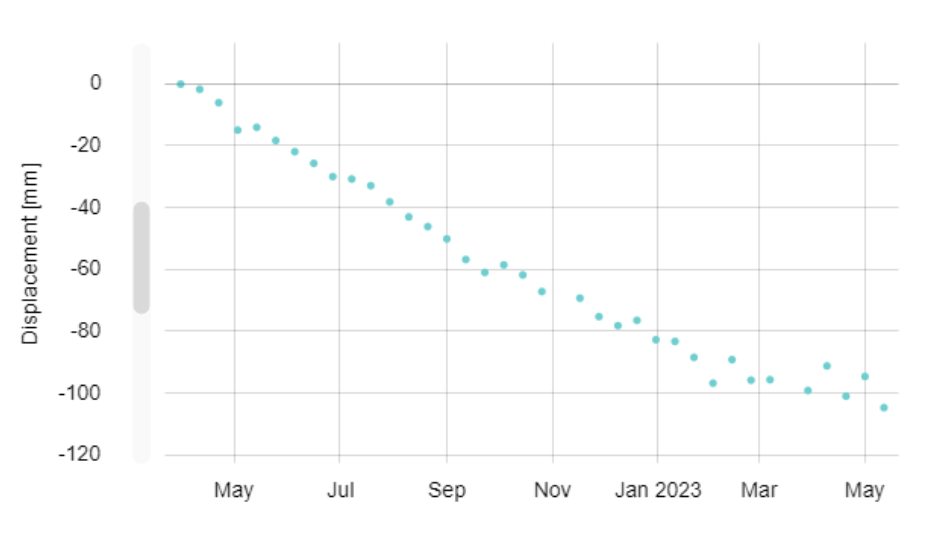

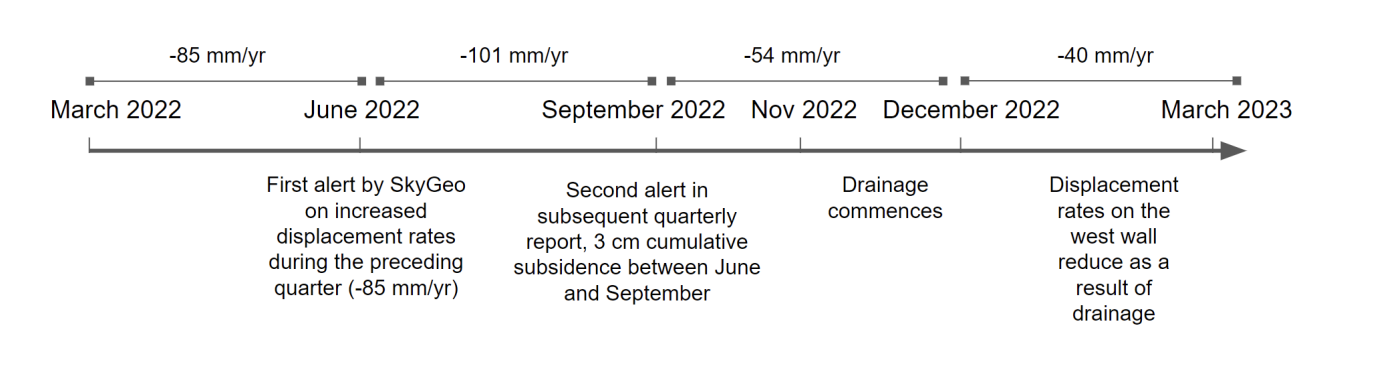

This section focuses on displacement estimations from the TerraSAR-X ascending satellite, which is particularly sensitive to slope displacements along the M15 wall due to its line of sight being parallel to the downward slope. The first early warning alert was issued by SkyGeo in June 2022 during the first quarterly review of pit displacements. Displacement rates between March 30, 2022, and June 26, 2022, were found to be around -85 mm/year, surpassing the historical baseline displacement rates of approximately -40mm/year. In the subsequent quarterly report of September 2022, the M15 west pit was again flagged for accelerated displacements. Notably, the M15 west wall experienced a subsidence of over 3 cm between June and September 2022, marking the most significant subsidence observed on the wall face during the monitoring period as indicated by Figure 9.

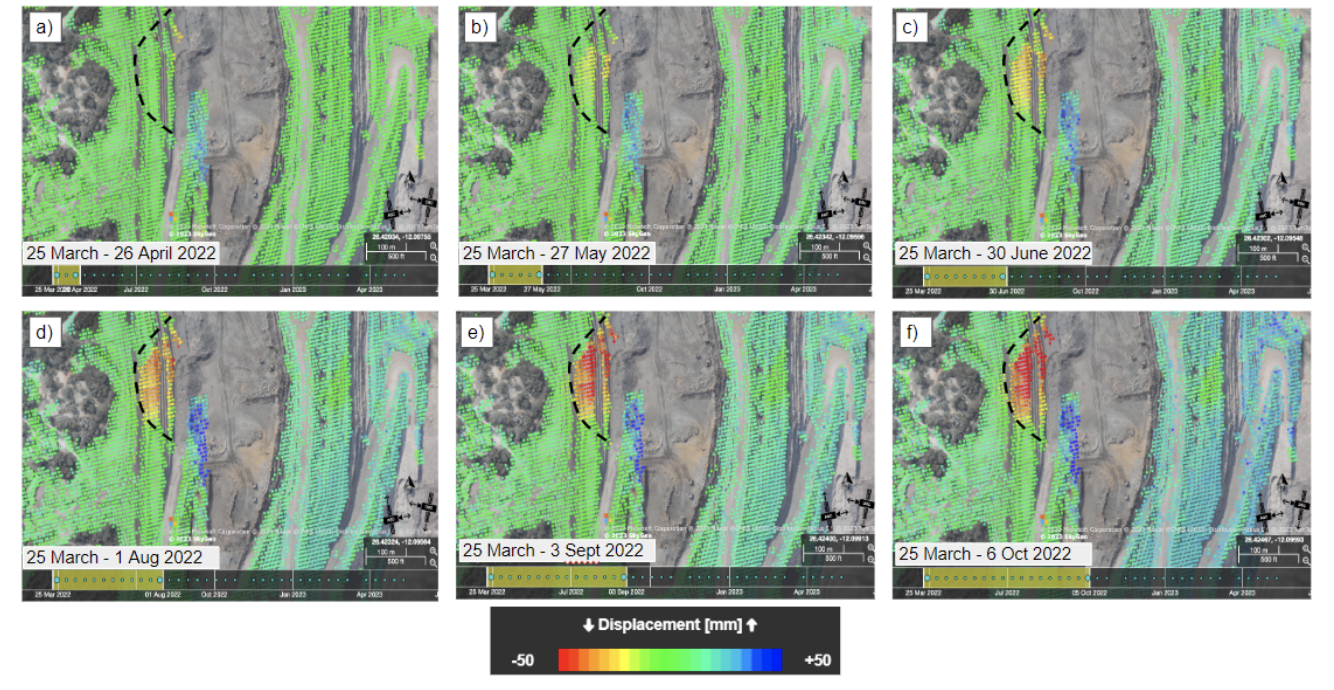

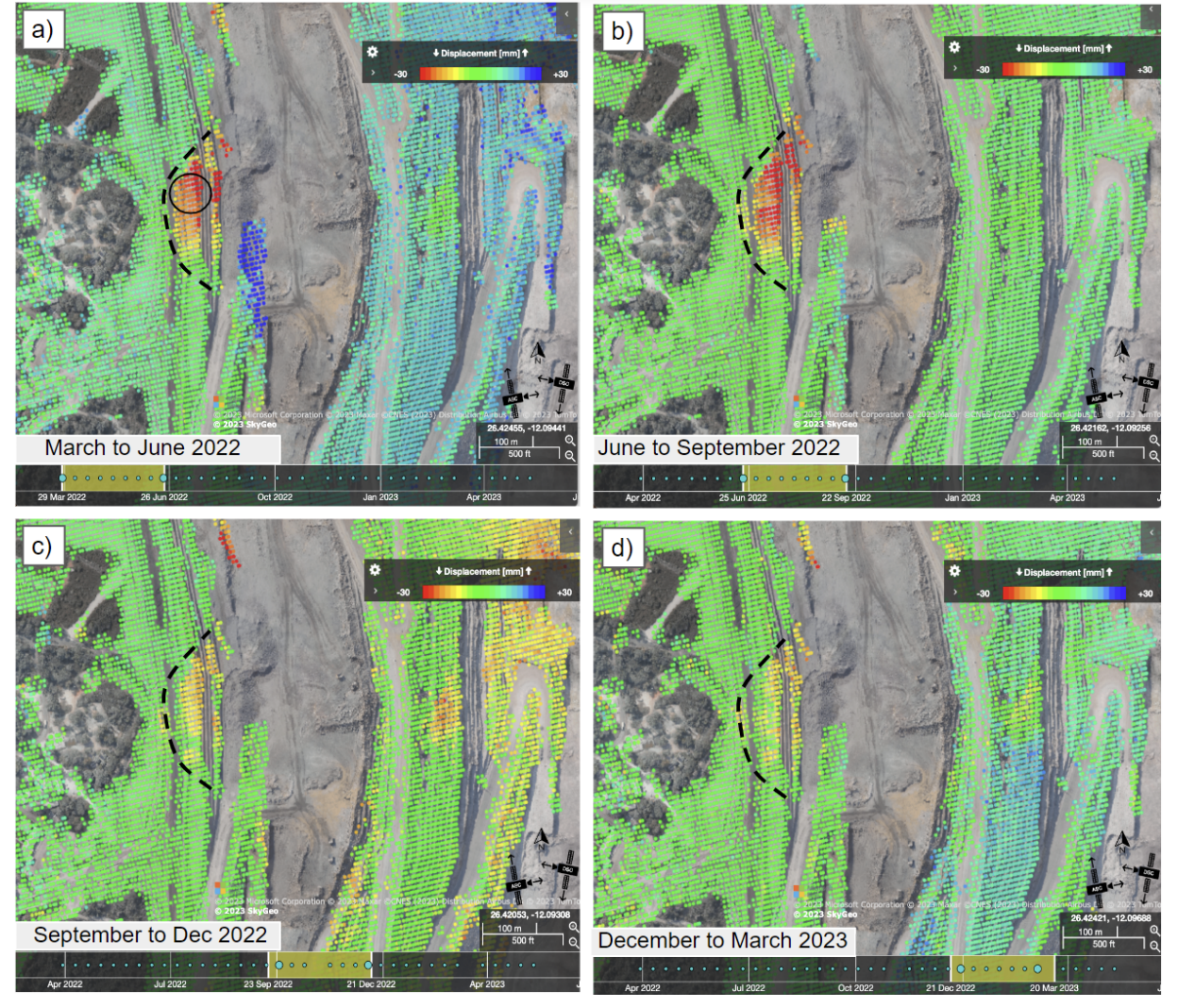

In addition to the increased magnitude of displacements, notable spatial patterns were detected as depicted in Figure 10. Movement was observed on multiple benches, starting from the base of the wall and spreading radially and laterally, resulting in a circular subsidence pattern. This was considered a precursor to a planar failure along the slope face. Given that many types of failures are influenced by groundwater conditions and seismicity, the presence of groundwater daylighting structures and nearby blasting activity led to the hypothesis that these factors contributed to the failure mode. Consequently, the monitoring reports were updated to a monthly frequency and eventually a biweekly frequency to track the failure precursor in a more timely manner.

Figure 7 Sentinel-2 imagery showing the active mining and pushback of Main pit’s west wall between May (a) and November (b) 2021 period.

Figure 8 Sentinel-1 Ascending data over the area of interest showing time series of displacements from 2019 to 2022 (R) and a heatmap of the rate of displacement over the same period. The rate of displacement is an estimated average of 40 mm/year away from the Line of Sight of the satellite which can be interpreted as subsidence.

Figure 9 The time series and cumulative displacement from TerraSAR-X ascending indicated over 10cm of displacement occurred during the entire time period between March 2022 and April 2023

Figure 10 TerraSAR-X ascending data indicating the changing displacement rate and spatial extent of displacements on the M15 wall between March and October 2022 (a to e). Semi-circular subsidence pattern indicated by the black dashed line.

4. Results

As a result of the increased displacements alerted by InSAR as well as other instrumentation, a dewatering plan was developed.

4.1 Depressurization

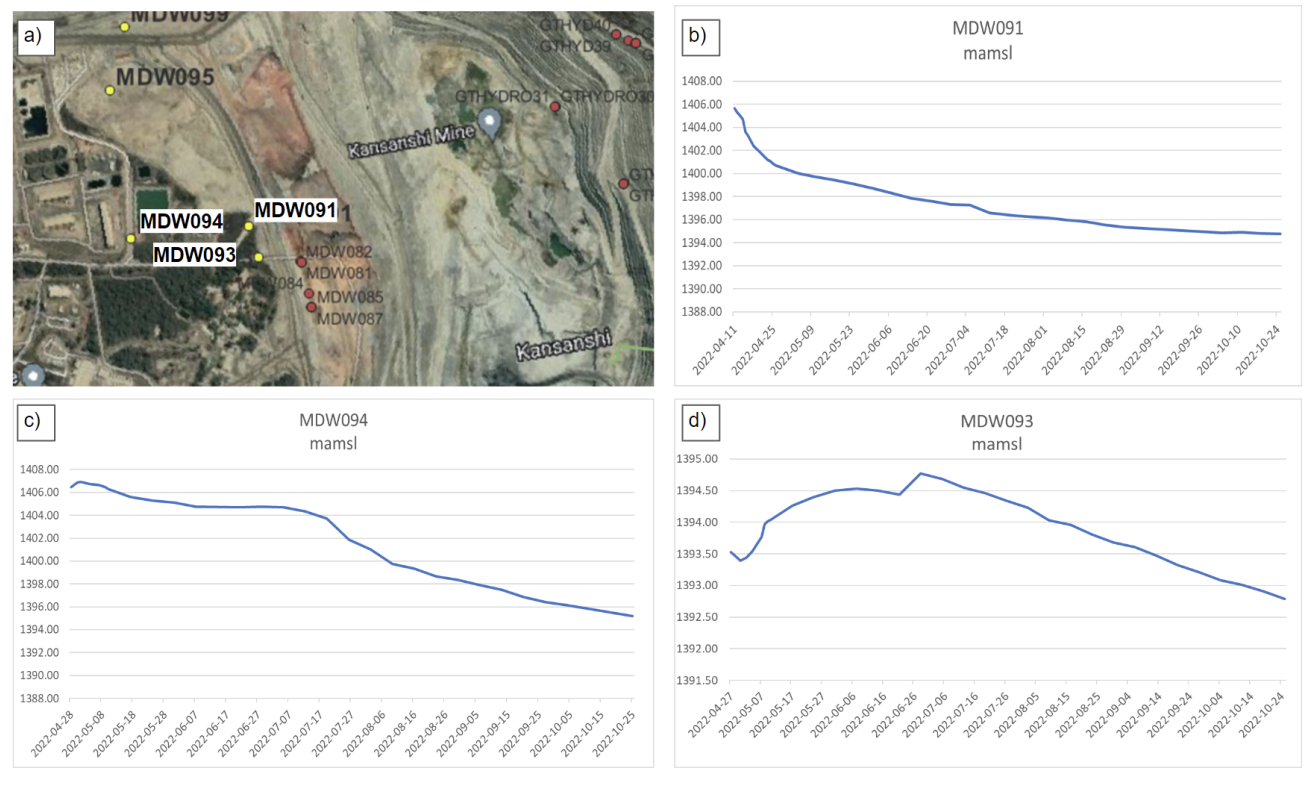

The drainage commenced in November 2022 with horizontal drains installed to a depth of 120m and spaced 150m apart at -5° inclination in specific locations. The drains were not cased. The response to groundwater elevations were monitored using the Vibrating Wire Piezometer (VWP) network over the mine as shown in Figure 11.

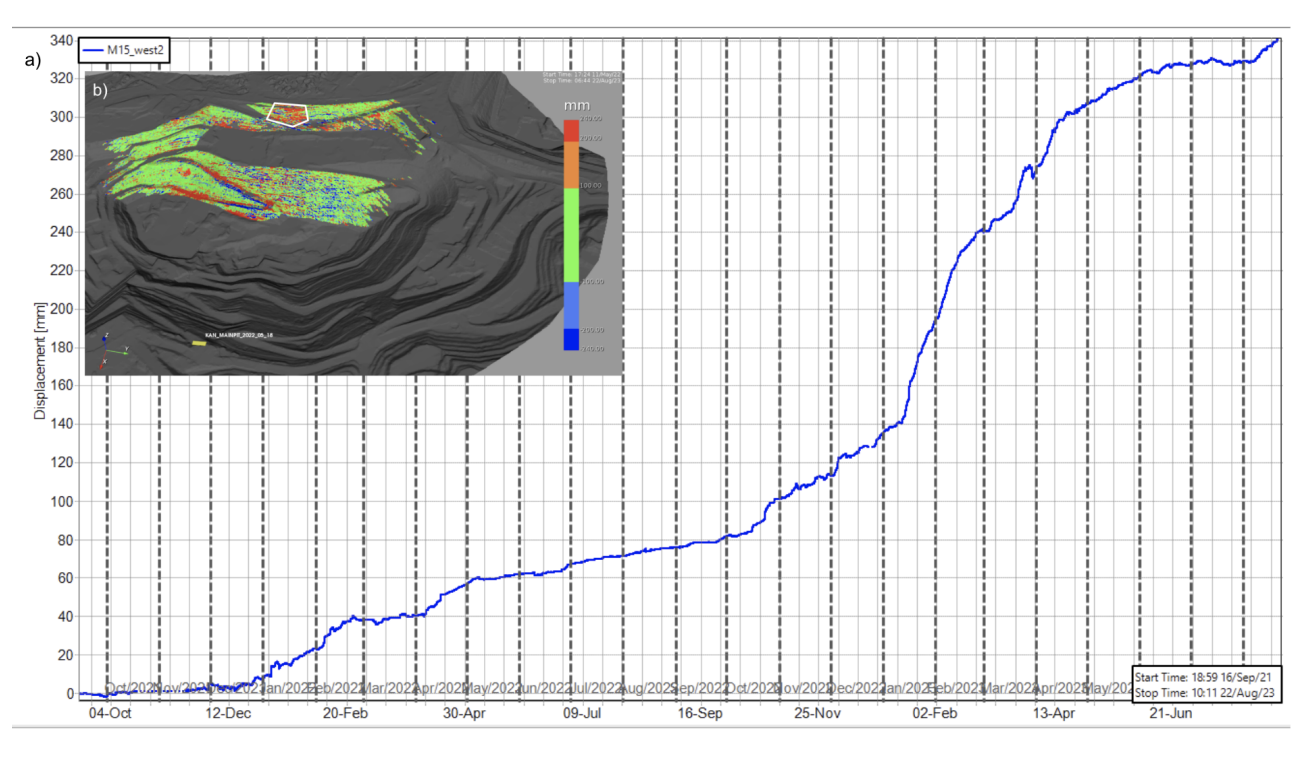

The depressurization drilling began in November 2022 and lasted until December 2022. During this period, the rate of displacement estimated with InSAR on the wall showed major reduction going from -101 mm/year to -53.4 mm/year as depicted in Figure 12.

The circular spatial subsidence pattern was replaced by local spots of continued displacement. These regions were at the base of the pit wall, at the crest, and on certain benches further south of the originally displacing area where other mining activities were ongoing. This is depicted in Figure 13.

4.2 Challenges in the rainy season

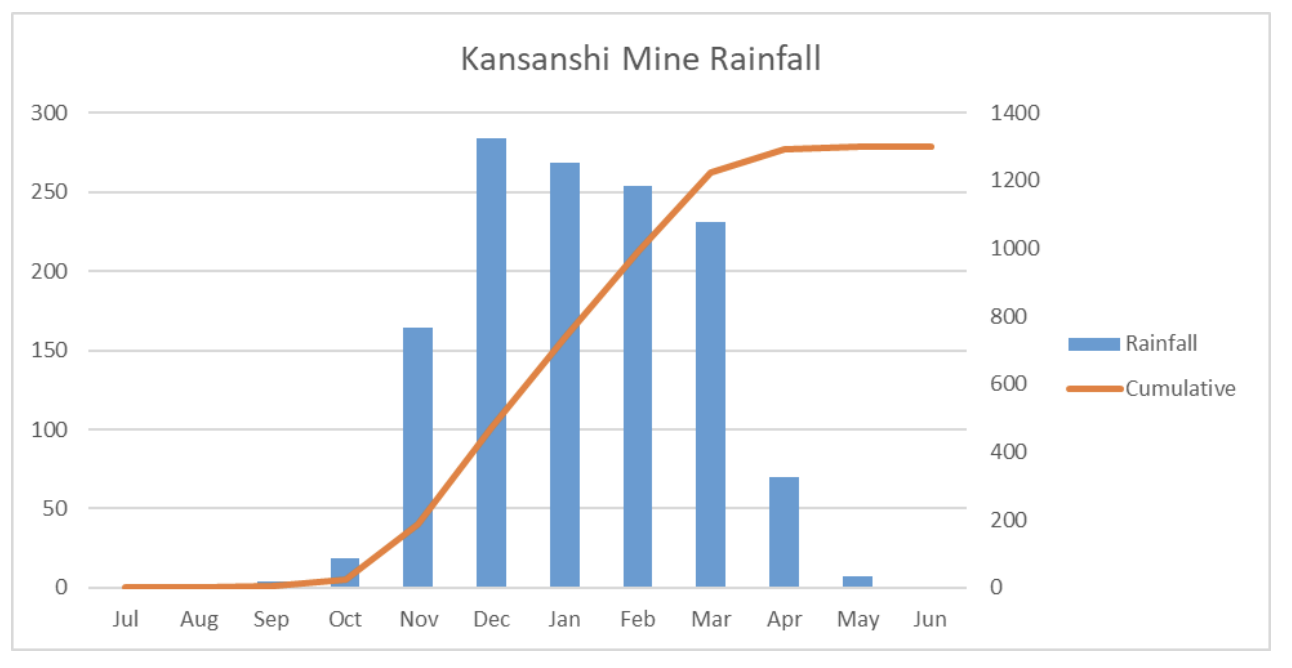

Zambia is classified as having a sub-tropical climate which is characterised by seasonal rainfall. The wet season typically occurs between October and April. The average annual rainfall is approximately 1.3m/year with the evaporation of approximately 1.1m/year. Figure 14 shows the typical rainfall figures for the Kansanshi mine measured using onsite instrumentation.

Rainfall leads to erosion with wash outs along pit slopes, erosion gullies can exacerbate existing slope stability issues causing water infiltration into the slope. Since the primary hypothesis was that the observed displacements were a precursor to a circular failure, there was a high urgency of managing the remediation before the rainy season arrived. The installed horizontal drains also had an additional benefit of regularly removing infiltrated rainwater from the unstable region.

It was well noted that despite the impact of the rainy season, displacement rates did not return to pre-intervention levels indicating that the slope had been successfully stabilised. This is highlighted in Figure 13 where the displacement rates stabilise around -56.3 mm/year with a further reduction to -40.3 mm/year which is in sync with the abatement of the rainy period.

The deterioration of the Main 15 upper area, due to rainfall is shown in Figures 15-16. Displacement recorded from the GBR shows an increase in displacement rate during both rainfall seasons 2021/2022 and 2022/2023, shown in Figure 17. The material does show delayed acceleration in the 2022/2023 season. The total movement recorded was 317mm over 19 months, with a velocity of 0.56 mm/day. This displacement is not seen during daily operations and if it was not for the InSAR monitoring focus would not have been placed on this area until it was too late to remediate the area. The erosion and infiltration of rainwater reactivated the material and caused acceleration of the material mass during the 2022/2023 wet season.

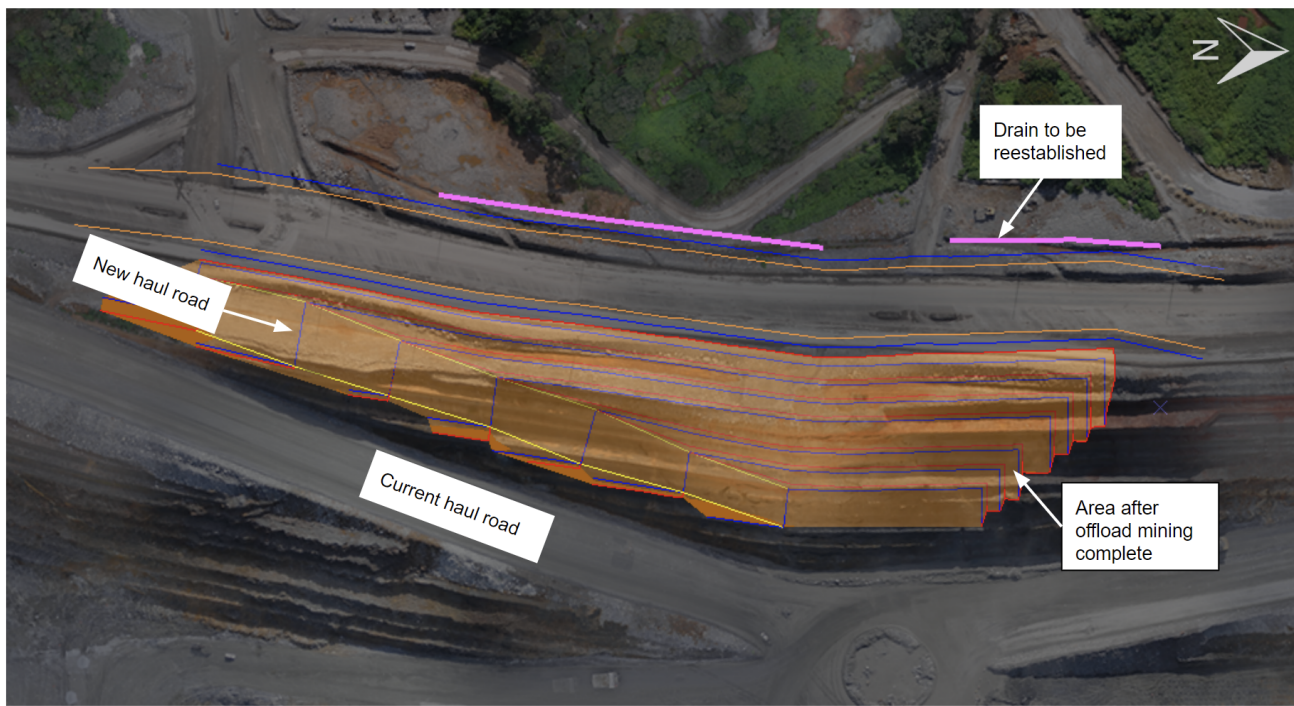

Ultimately the decision was made to unload the crest region to ensure stability of the area until the end of the cuts mining life. The planned layout of the area is shown below in Figure 18.

5 Conclusion

The InSAR monitoring was invaluable for Kansanshi Mine to get long-term pre-warning of an area that started moving in November of 2021 and has been showing displacements every wet season. The depressurisation drilling has slowed the movement, but the movement was reactivated during the 2022/2023 rain season. This however has given Kansanshi Mine the ability to plan and implement unloading of the crest before the 2023/2024 rain season.

References

Bieniawski, Z.T. 1989, Engineering Rock Mass Classifications: A Complete Manual for Engineers and Geologists in Mining, Civil, and

Petroleum Engineering, Wiley

First Quantum Minerals. (2022). Ground Control Management Plan Kansanshi Mine. GCMP 001. Unpublished internal company

document.

First Quantum Minerals. 2022. Rock Engineering. Unpublished internal company document.

Gray, D., Lawlor, M., Stone, Robert. 2020. ‘Kansanshi operations, North West Province, Zambia. NI 43-1010 Technical Report’’

More O'Ferrall, G. C., and N. S. Simbile. "Addressing pit wall instabilities in Africa’s largest open pit copper mine." In Slope Stability

2020: Proceedings of the 2020 International Symposium on Slope Stability in Open Pit Mining and Civil Engineering, pp. 1507-1520.

Australian Centre for Geomechanics, 2020.

Sentinel-1B in-flight anomaly summary report. (n.d.).

https://sentinel.esa.int/documents/247904/4819394/Sentinel-1B+In-Flight+Anomaly+Summary+Report.pdf

Figure 11 The location (a) and time-series of three VWP: b) MDW091 c) MDW093 and d) MDW094

Figure 12. Timeline of events and displacement rates over the M15 west pit wall. Approximate location of displacement rates shown in Figure 13.

Figure 13 Evolution of the circular subsidence pattern on M15 West Pit wall. a) March to June 2022, b) June to September 2022, c) September to December 2022, d) December 2022 to March 2023. The black circle on a) refers to the approximate location of the displacement rates quoted in Figure 12.

Figure 14 Cumulative and monthly rainfall (mm) for Kansanshi Mine

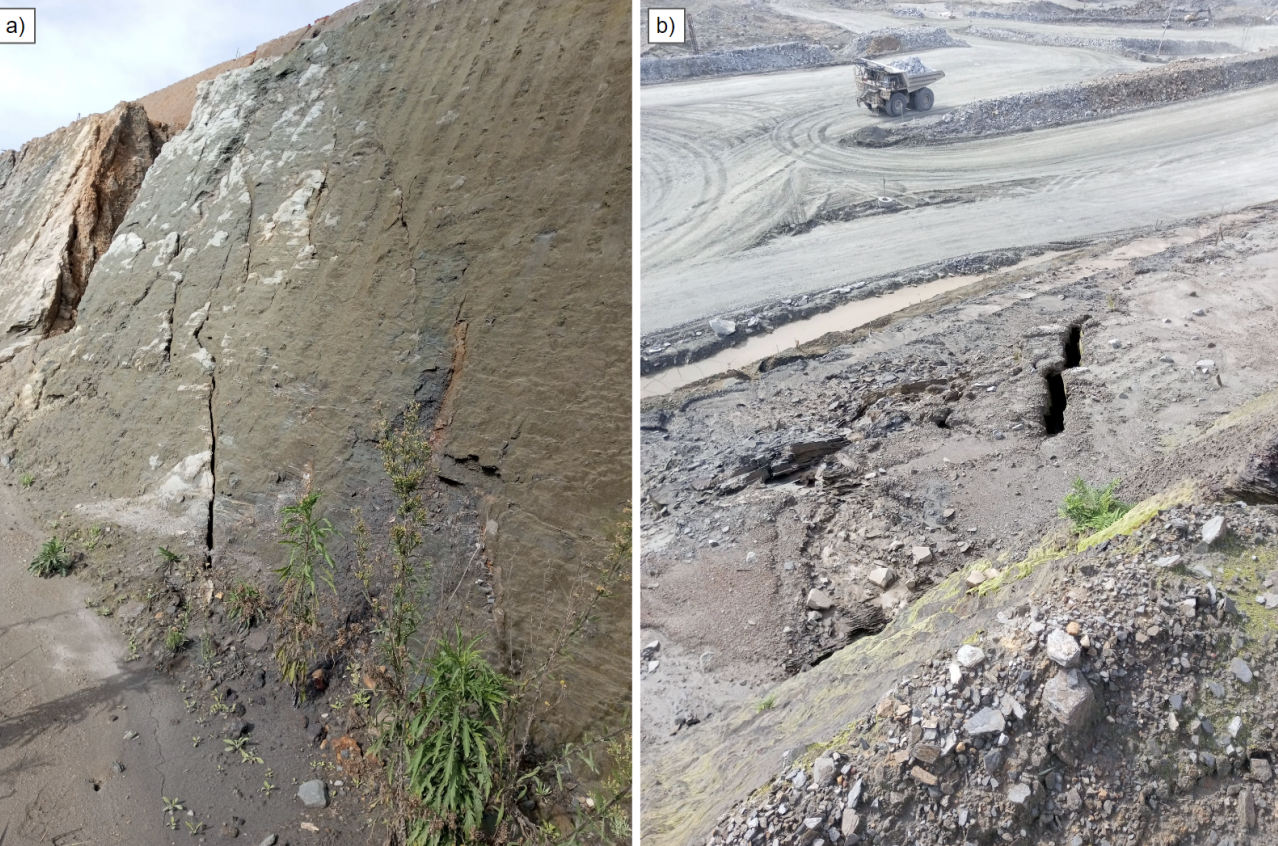

Figure 15 Both a) and b) show open joints and erosional gulleys

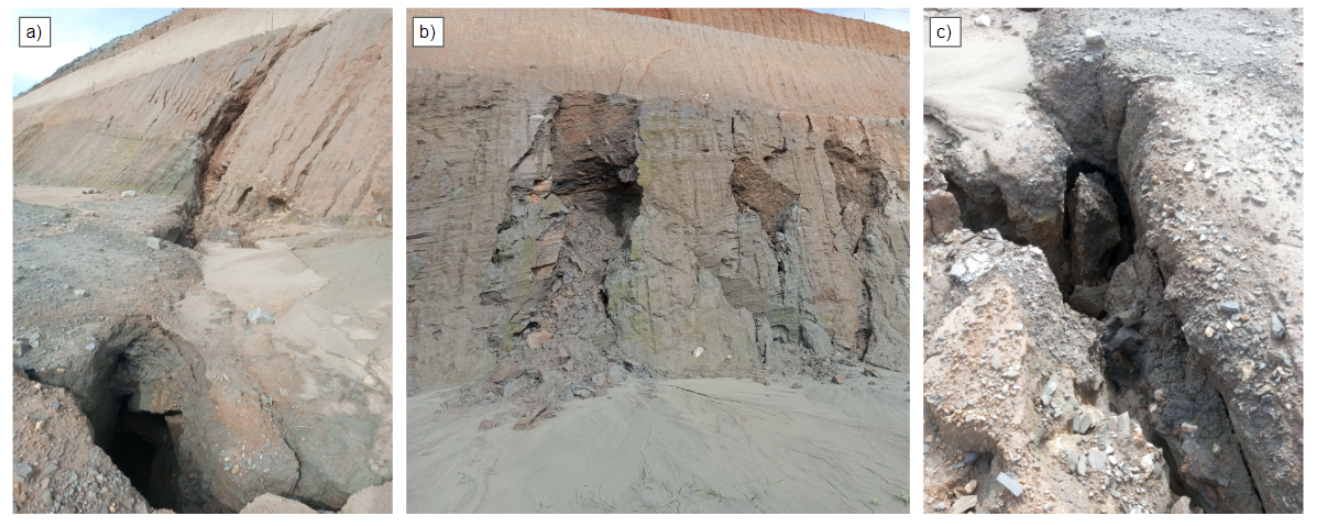

Figure 16 The effect of rainfall on the dispersive saprolites showing piping in the slope. a) Erosional channel through the joint, b) Fallout of saprolite material from the joints, c) erosion channel.

Figure 17 Main 15 ground-based radar data a) Average time series graph from 16 September 2021 to 22 August 2023 b) Inset displays the slope face area for which the time series graph was generated overlain on a displacement heat map from 11 May 2022 to 22 August 2023 set to ±240mm color scale (blue is -240mm, red is +240mm) in Line of Sight of the radar

Figure 18 M15 Fault zone crest unloading

Case Studies

-

Potash Mining Company

Leveraging SkyGeo’s holistic approach to managing geotechnical risk, the client now identifies sinkholes as early as possible and minimizes the probability of a catastrophic collapse causing dike failure.