SkyGeo’s Experience in the Mining Industry

Detect Instabilities Early

Mine stability monitoring provides continuous geotechnical risk monitoring to identify areas of abnormal surface movement. By assessing time-dependent shape changes in Antares, geotechnical domain experts can identify patterns of instability. This is a way to directly improve asset management in mining operations.

Early Warning

Three of the largest companies in the industry have selected SkyGeo as their preferred InSAR partner. We pride ourselves on being world-class field application engineers and are on a mission to make InSAR the standard remote monitoring solution for the mining industry. Regular monitoring provides detailed, comprehensive information about instability. Our Antares platform provides early warnings when potential problems are detected.

SkyGeo is the market leader in InSAR analysis to detect and measure surface movements and understand them in terms of structural or groundwater changes.

Hundreds of customers worldwide have been working with SkyGeo products and consultants for over a decade. Every mine is different, and we've proven that there's no one-size-fits-all InSAR solution.

Stability by to dam

The mining sector has workflows and safety practices unlike any other industry. We can help improve site uptime by using satellite data to predict maintenance. Areas that move with unexpected patterns require more attention than areas with a stable surface. Groundwater is known to play a key role in this process, and we help you better visualize its role. Our engineers and geoscientists work with you and your geotechnical team to ensure maintenance scheduling is optimized and costs can be reduced.

Environmental risk management is a serious issue in mining. Will it ever be possible to completely prevent a failure by using data? We are beginning to understand the predictive power of these millions of remote sensing measurements, but they require a specialist to translate them into a correct and easily understandable safety statement.

Stability Monitoring

Avoid surprises – risks in mining have consequences for the immediate surroundings and the environment.

Optimize the deployment of security personnel and equipment.

Discover new insights into time-dependent risks.

Stability by of Storage Facilities

Every mine has several areas of high geotechnical risk, each requiring a specific iterative assessment. Tailings dams represent a particular risk category. Due to recent environmental problems, most mining experts are now looking for continuous monitoring systems to better predict instability.

Solid tailings are often used as part of the construction itself, and because they are liquid or a slurry of fine groundwater particles, significant instabilities arise in various ways that are often not fully understood. With InSAR, we can help with this understanding: we characterize and quantify these time-dependent degradation processes on a broad scale and identify various dynamic patterns. Continuously monitoring these patterns is now a proven method for ongoing risk management.

The deployment approach of remote and local sensors is different for each of the three raised tailings dam designs, the upstream, downstream, and centerline.

Measurements Convert in Insights

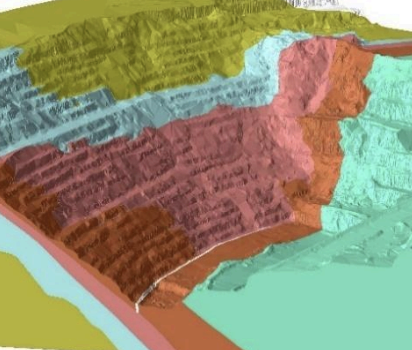

In (stability evaluation of) piles and landfills, as well as high-rise or mine slopes, we consider groundwater levels, soil conditions, and other geotechnical influences. These factors influence both the InSAR measurements and the resulting insights. We are building a library of relevant deformation patterns.

We create short-term "iso-distortion" maps each time the satellite acquires an image and range distortion in the mine over the last few days using a four-stage "traffic light" warning system. For most clients, we typically display two different lines of sight, showing different parts of the mine. These contour maps differ from our time-series products.

Contact our specialists to learn more about the relative merits of both products and how they can help uncover various stability issues.

Sufficient Coverage by of Mines

InSAR stability monitoring can provide early warning of ground motion across the entire mine environment, including tailings storage facilities. This warning system triggers managers when they need to take action for visual inspection or deploy other resources, such as ground-based radar or drone-based systems, for an emergency site survey. A key advantage of our system is that the InSAR data is pre-processed in our platform according to a set of threshold criteria for ground motion dynamics, resulting in a location-specific traffic light function. The data we share with your company integrates seamlessly with all standard mining software. Each time satellites revisit, a new dataset can be made available. For some locations, this is every two weeks, while others are monitored every 5-6 days.

The World’s Most Transparent and Reliable InSAR-Analysis

At SkyGeo we know how the complex InSAR machine works inside and out; we know what works well – and what doesn’t when assessing all the different aspects of the mine stability. We have built our own code base to do interferometry; we do not rely on black-box third party software. We task and work with all available satellites and configure a service to optimize continuous risk monitoring. Moreover, we have built a progressive rigorous process to do Quality Assurance auditing of our InSAR for Mining applications that has met the rigorous quality standards imposed by some of the largest and most demanding organizations in the world like ExxonMobil and Shell.

Examples of our work

-

Potash Mining Company

Leveraging SkyGeo’s holistic approach to managing geotechnical risk, the client now identifies sinkholes as early as possible and minimizes the probability of a catastrophic collapse causing dike failure.

-

Kansanshi Copper Mine

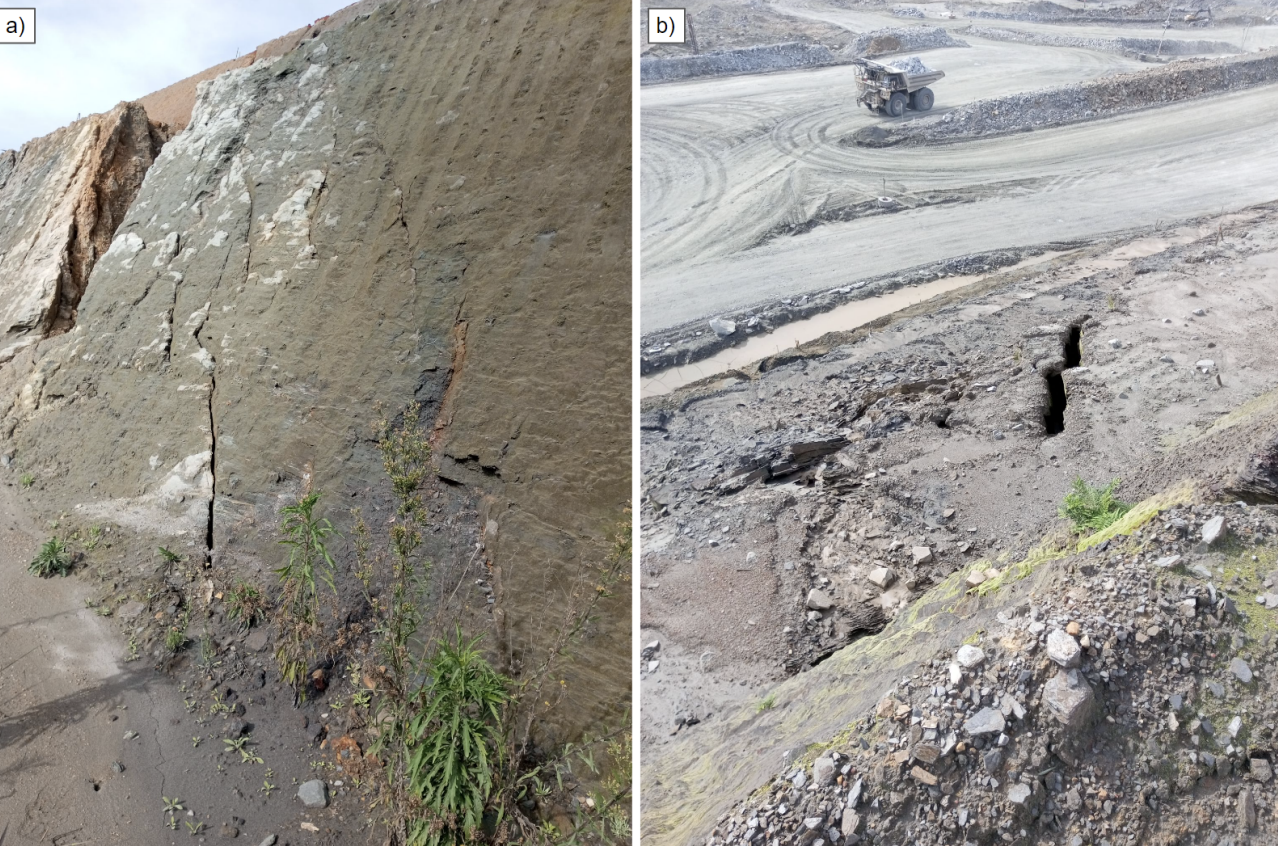

Stabilisation of open pit wall movements detected by InSAR using horizontal drains

-

Vedanta Zinc International

Informing an operational slope stability feedback loop: integrating InSAR monitoring and 3D modelling at Gamsberg Mine

Frequently Asked Questions

-

InSAR is used to monitor deformation across open pits, waste dumps, tailings facilities, and surrounding infrastructure. It provides wide-area time-series visibility that complements on-site monitoring, helping teams understand where movement is changing and where attention is needed.

-

Yes—when interpreted correctly. Time-series trends can reveal subtle changes that may indicate evolving conditions. Expert interpretation is important to separate signal from noise and to understand what patterns are meaningful for geotechnical risk.

-

No. InSAR complements ground-based monitoring and inspections. It can help prioritise where to look and provide broader context over time, but decisions should integrate multiple data sources and engineering judgement.

Let Us Know How We Can Help You

info@skygeo.com