InSAR Technology Reduces Landslide Displacement by 50% at the Kansanshi Mine

The Kansanshi Mine , located in Zambia, stands out as Africa's largest open-pit gold and copper mine. With pits extending up to 3 km and situated in a geologically complex environment of dolomite, marble, and schistose rock, slope stability is crucial for the mine's safe and efficient operation. First Quantum Minerals Ltd. (FQML) has achieved a remarkable 50% reduction in slope displacement through the implementation of advanced interferometric synthetic aperture radar ( InSAR ) technology.

Image credit: first-quantum.com

Risks and focus on Slope Stability.

The frequent slope instability at the Kansanshi Mine was due to multiple factors, including eroded materials, high water pressure, and structural variations in the rock. These conditions increased the risk of landslides, which could lead to operational disruptions and endanger worker safety. Ensuring stability in critical areas such as the upper slope of M15 became a top priority for FQML.

Challenges at the Kansanshi mine.

Eroded materials : Constant erosion weakened the integrity of the slopes, increasing the likelihood of landslides.

High water pressure : The accumulation of water on the slopes increased the pore pressure, contributing to the instability of the terrain.

Structural variations : The complex geology of dolomites, marbles and schistose rock presented additional challenges to maintaining the stability of the slopes.

Innovative solution: InSAR

In response to these challenges, FQML adopted InSAR technology in 2021, provided by SkyGeo , to monitor and manage ground movement more effectively. The InSAR system uses interferometric synthetic aperture radar to obtain high-resolution images of the terrain, enabling the precise detection of minute displacements that could indicate future inconsistencies.

What is InSAR technology and how does it work?

InSAR technology is a remote sensing technique that uses multiple radar passes to measure ground displacements with millimeter precision. By comparing the phases of radar waves reflected from the Earth's surface at different times, InSAR can detect even the most subtle ground movements.

High resolution and accuracy : InSAR provides detailed data on ground movement, enabling early identification of dangerous displacements.

Continuous monitoring : Unlike traditional methods, it allows constant, real-time monitoring of slope stability.

Wide coverage : The technology can cover large geographical areas, which is ideal for open-pit mines like Kansanshi.

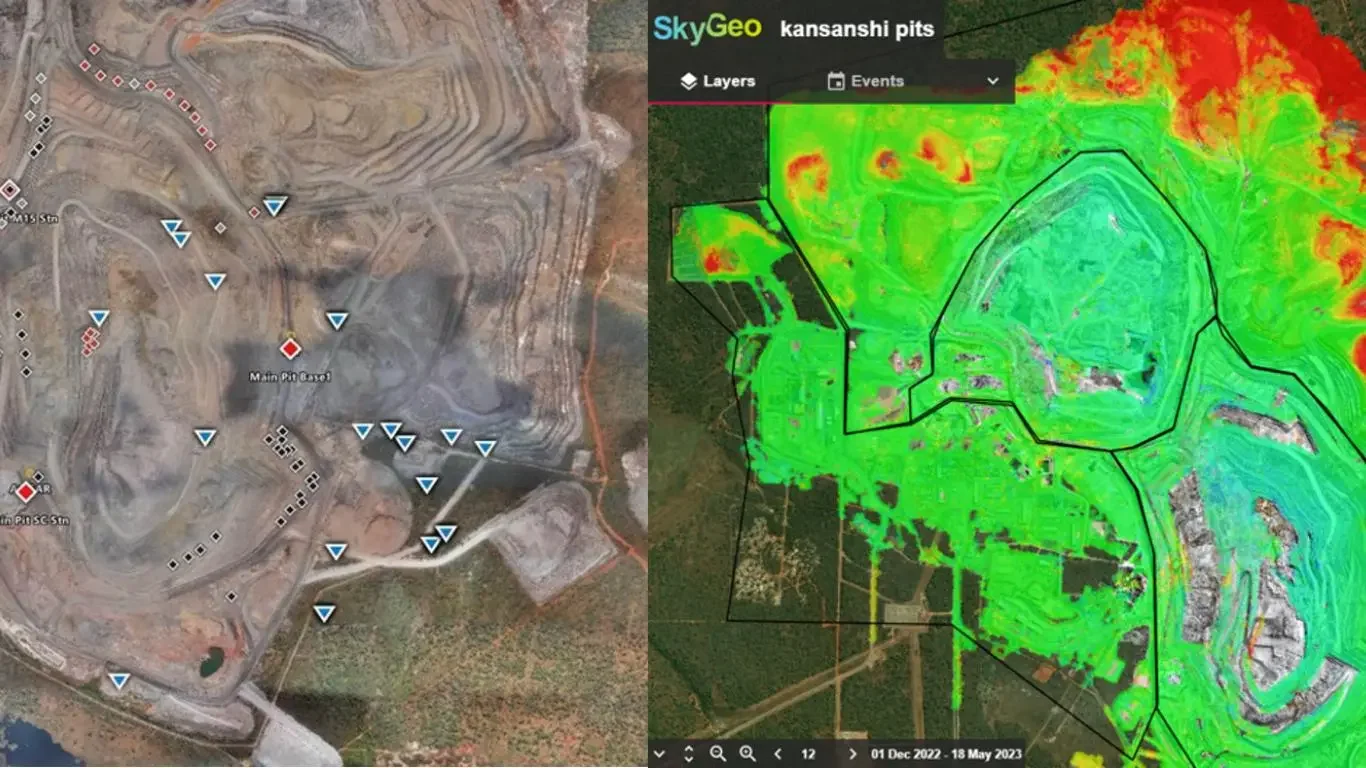

Monitoring was conducted using the following methods (left image): visual inspections, ground-based radar, robotic total station setups (red diamonds), prisms with total stations (black diamonds), and piezometers (inverted blue triangles). InSAR was used from 2021 to supplement existing ground-based systems on a quarterly basis and cover a larger area (right image). The frequency was changed to monthly when an alert was issued for the M15 wall and increased to every 11 days as InSAR became a critical monitoring tool.

Big difference in safety and costs.

The implementation of InSAR has had a significant impact on the safety and operating costs of the Kansanshi Mine. Through continuous data collection and analysis, SkyGeo has issued early warnings that have allowed FQML's geotechnical team to proactively mitigate risks.

Key benefits of InSAR in Kansanshi

Risk reduction : The ability to detect minimal displacements has allowed for early intervention, reducing the risk of major landslides.

Cost optimization : Landslide prevention and early intervention have reduced the costs associated with repairs and downtime.

Improved worker safety : By ensuring the stability of the slopes, a safer working environment has been created for mine employees.

Implementation of proactive solutions.

Thanks to alerts issued by InSAR, FQML has been able to implement effective solutions such as the installation of horizontal drains and relief wells to reduce water pressure on the slopes. Furthermore, SkyGeo's Antares platform has facilitated the prioritization of high-risk areas using color-coded risk levels, enabling rapid interpretation and response by the geotechnical team.

Real-time monitoring and alerts.

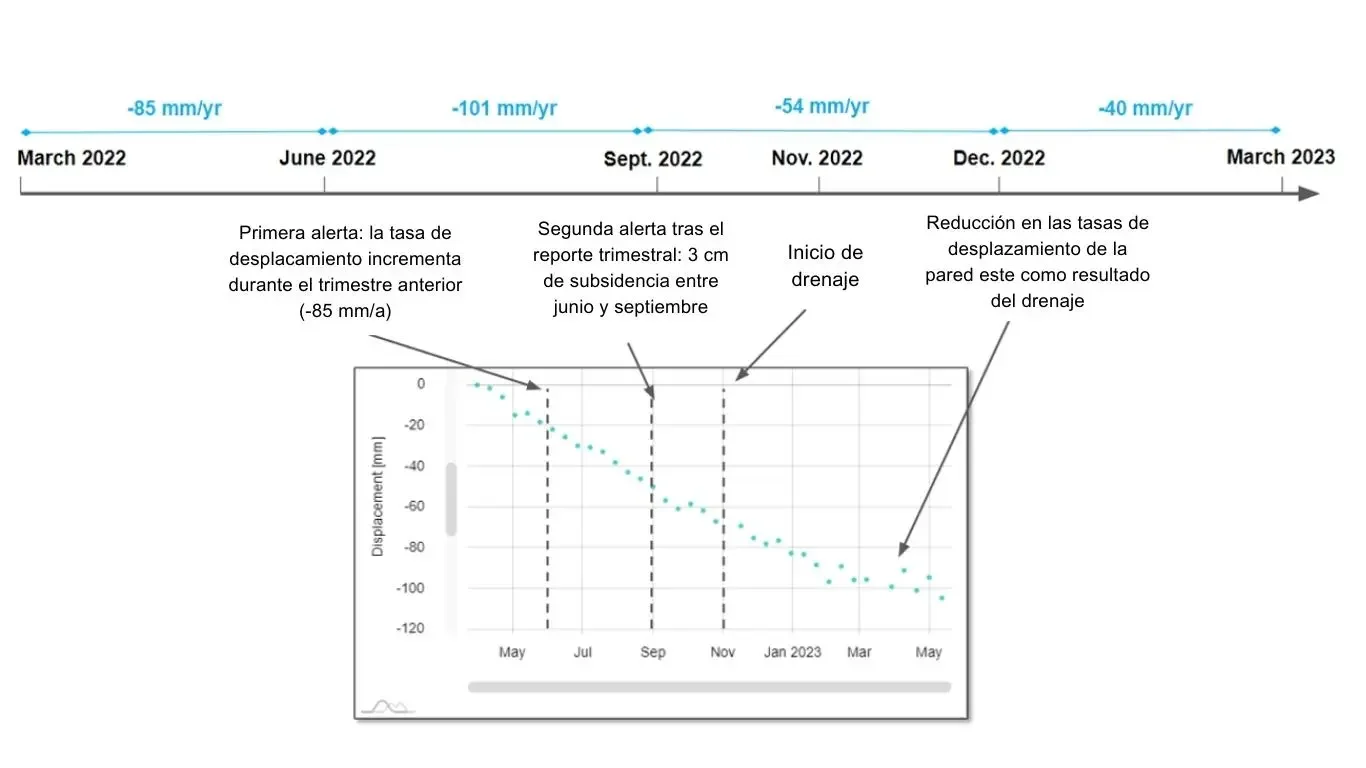

In mid-2022, data from InSAR revealed progressive displacements along the western face of the M15 slope, with rates as high as -101 mm/year . These displacements formed a circular subsidence pattern, indicating a potential slope collapse. Thanks to real-time monitoring, FQML was able to intervene promptly to avert a potential disaster.

Tangible results

50% reduction in displacements : The implementation of InSAR has significantly reduced slope movement, improving the overall stability of the mine.

Prevention of operational interruptions : The ability to detect and mitigate risks has allowed the continuity of mining operations to be maintained without major interruptions.

Increased operational confidence : Technology has strengthened FQML's confidence in its risk management strategies and the security of its facilities.

Topographic surveys further assessed the situation, and subsequent updates and consultation sessions led us to focus on these areas. From that point onward, topographic surveys in this part of the site were intensified. The timeline illustrates the sequence of events from June 2022 to November 2022, as well as the positive outcome. All of this was made possible by the proactive measures implemented with guidance from SkyGeo and InSAR.

Significant progress in Mining Risk Management

The adoption of InSAR technology has been a game-changer for First Quantum Minerals Ltd. at the Kansanshi Mine. By providing a reliable, high-resolution source of ground movement data, InSAR has enabled proactive management of risks associated with slope instability, ensuring worker safety and the continuity of mining operations.

To learn more about advanced geotechnical monitoring solutions and risk management technologies, visit our website and explore our related articles on InSAR technology.