Potassium Mining Company Prevents Dam Damage with Advanced Sinkhole Scanner

In the mining sector, the safety and stability of infrastructure are paramount. SkyGeo , in collaboration with a company in the Potassium Mining sector, took a significant step toward improving dam safety by implementing the innovative Sinkhole Scanner . This technology has enabled safety engineers to obtain accurate and up-to-date data, preventing potential damage and ensuring the integrity of mining operations.

Challenges in traditional dike monitoring

Before adopting the Sinkhole Scanner, the Potassium Mining Company faced serious challenges in assessing the stability of its dams. The traditional LiDAR leveling method , which involved leveling campaigns every six months, proved insufficient to detect rapid and uneven variations in dam height.

Lidar Leveling: Limitations and Operation

Lidar leveling is a remote sensing technique that uses lasers to measure distances and create detailed three-dimensional maps of the terrain. In the context of the Potassium Mine, Lidar leveling campaigns were carried out every six months, placing monuments every 500 meters and, in suspiciously elevated areas, every 200 meters. Although this technology provides an overview of the dam's topography, it has several limitations:

Update frequency : Semi-annual campaigns do not allow for the detection of rapid changes, which can delay the identification of emerging sinks.

Spatial resolution : The spacing of monuments leaves large areas without continuous supervision, making it easier for sinks between stations to go unnoticed.

Analysis complexity : Interpreting Lidar data requires detailed analysis, which can delay critical decision-making in emergency situations.

These limitations led the Potassium Mining Company to seek a more efficient and accurate solution for the continuous monitoring of its dams.

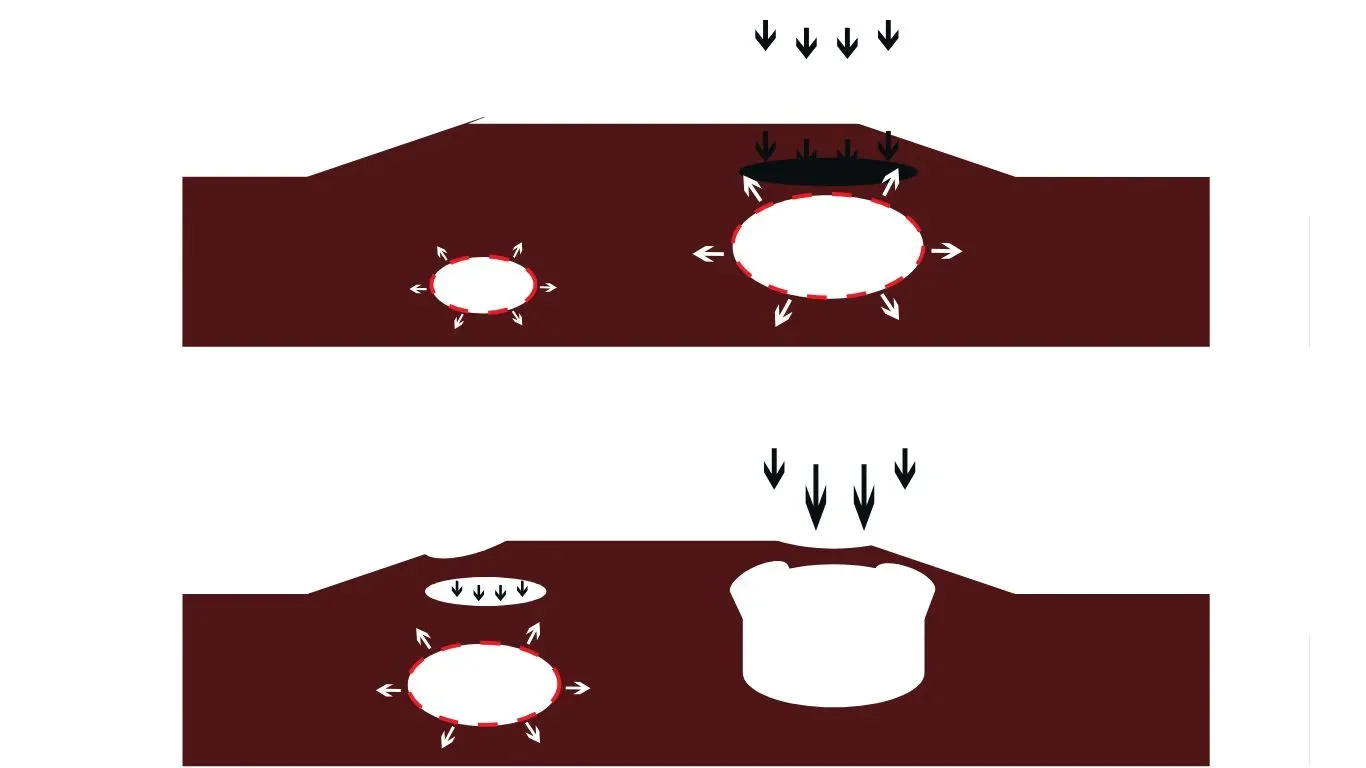

Geological cross-section of the situation. Before a sinkhole collapses, the ground surface subsides over the forming cavities. This appears as localized subsidence depressions with a diameter of 10 to 100 m, which are visible on the sinkhole scanner.

Cutting-edge solution: Drain Scanner

The introduction of the Sinkhole Scanner has revolutionized dam monitoring at the Potassium Mine. This advanced technology provides 10 times more information and 25 times more updates , enabling a detailed and timely assessment of dam stability.

What is a Drain Scanner and how does it work?

The Sinkhole Scanner is a geophysical monitoring tool that uses high-precision sensors distributed along the dike to detect deformations and subsidence in real time. Unlike LiDAR leveling, this scanner takes continuous measurements, providing constant monitoring of the dike structure. Its operation is based on collecting deformation data using technologies such as synthetic aperture radar interferometry (InSAR) and high-precision GPS sensors. The Sinkhole Scanner's sensors collect data at regular intervals, allowing for immediate detection of any anomalies in the dike structure. Likewise, the high spatial and temporal resolution, with more than 20,000 measurements per km², ensures that there are no gaps larger than the diameter of a sinkhole between measurement points, offering detailed and accurate coverage.

The constant collection of data allows engineers to use machine learning algorithms to predict potential failures before they occur, facilitating effective preventative actions.

Key benefits of the drain scanner

High data resolution : With a significantly higher measurement density than the Lidar method, the Sump Scanner ensures comprehensive monitoring of every section of the dike.

Monitoring: The technology offers frequent updates, allowing engineers to detect subsidence and deformation in real time.

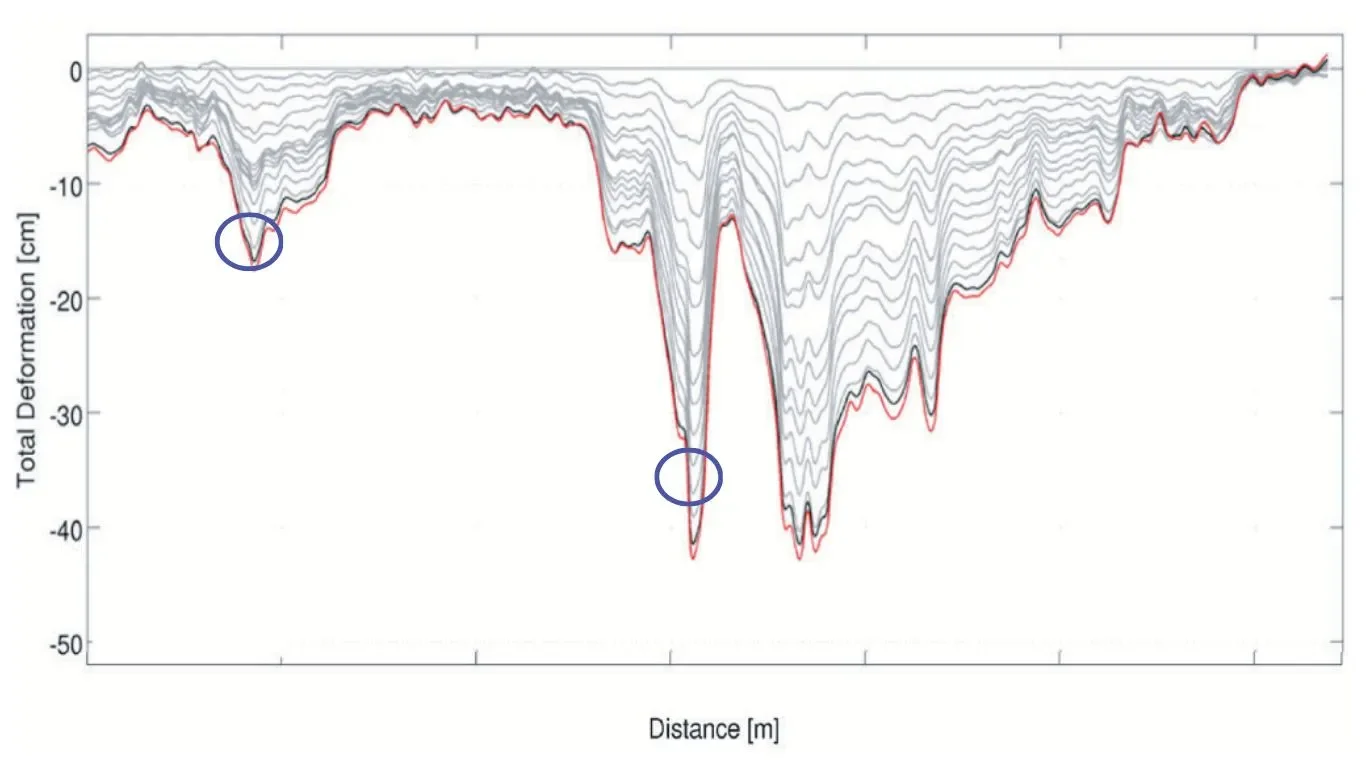

Advanced visualization : The incorporation of time series in cells 100 meters wide and 20 meters along the dike facilitates the visualization of the background at the crest of the dike.

Deformation profile along the crest, developing over a 12-month period. Background information on sinkholes indicates local accelerations of subsidence, as well as notable local deviations compared to anticipated regional subsidence trends.

Regional and Geophysical Impact

The use of the Sinkhole Scanner has not only improved sinkhole detection, but has also allowed Minera de Potasio to isolate and understand local subsidence patterns more effectively. This includes assessing active faults and regional geology, providing a comprehensive view of the factors affecting dam stability.

Since implementing the Sinkhole Scanner, Minera de Potasio has been able to prevent significant damage to its dikes. A prime example is the early detection of a factor that likely caused subsidence near the coastal area, approximately one year before it physically manifested. This proactive approach allows for on-site geophysical assessments and appropriate preventative maintenance.

A step forward in mine safety

The adoption of the Sinkhole Scanner has proven to be a valuable investment for the Potassium Mining Company , strengthening the safety and stability of its dams. By providing more accurate and up-to-date data, this technology enables proactive management of the risks associated with sinkholes, ensuring the continuity and safety of mining operations.